No products in the cart.

MMC - Modular Technology

Just few days on-site work

Most of the construction work are done in factory, so around two weeks after foundation are made, we need from 3 to 7 days to assemble the house.

On that stage you will have a house with external door, windows, finished roof, walls with internal and external insulation and acrylic plaster (or other finish depend on requirements) and internal walls.

Electrical installation will be pre-wired, with fusebox, and cables laid out, ready to connect sockets and switches.

Water piper also ready to connect all water and heating equipment.

On that stage you will have a house with external door, windows, finished roof, walls with internal and external insulation and acrylic plaster (or other finish depend on requirements) and internal walls.

Electrical installation will be pre-wired, with fusebox, and cables laid out, ready to connect sockets and switches.

Water piper also ready to connect all water and heating equipment.

- Fermacell board

- Styrofoam 100 mm

- Acrylic plaster

- Exterior window sills

- Windows

- Soffit

- OSB board

- Battens and counter battens

- Roof foil

- Roof tile

- Chimney

- Reinforcement

- Siding (option)

- Floor heating (option)

- Radiators

- Water installation

- Sewer installation

- Electric install

- Fire place

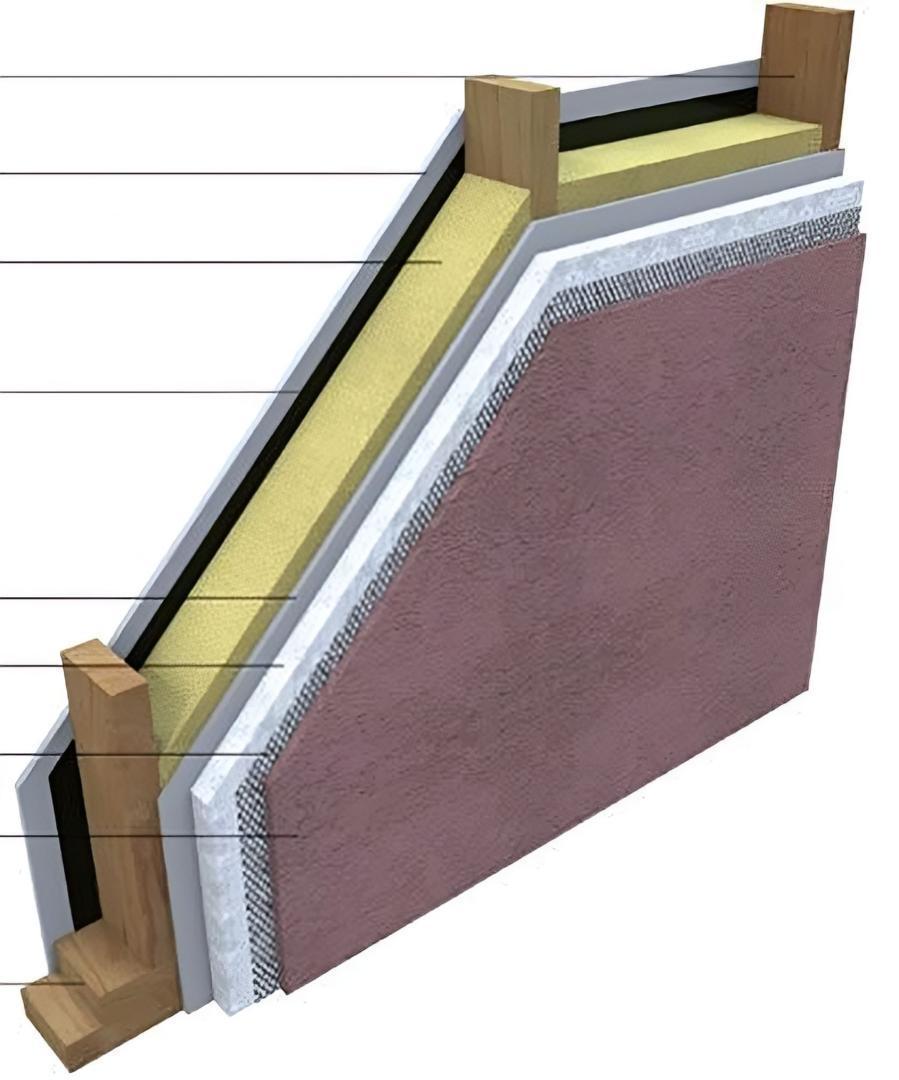

External wall

Houses are built with prefabricated wall and floor elements in a timber-frame system. KVH timber scantlings are chamber-dried and then impregnated.

The thermal insulation coefficient of the external walls is U=0.14 W/m2K (in comparison, a 50 cm thick ceramic hollow block wall – U=0.34), ensuring a significant reduction in the cost of heating the interior of the house.

The thermal insulation coefficient of the external walls is U=0.14 W/m2K (in comparison, a 50 cm thick ceramic hollow block wall – U=0.34), ensuring a significant reduction in the cost of heating the interior of the house.

- 12.5 mm FERMACELL fibre gypsum board

- Vapour barrier membrane

- Timber KVH 60 x 160, 4-sided planed

- ROCKWOLL mineral wool 160 mm. Non-combustible, with low thermal conductivity coefficient λD=0.036 W/mK.

- 12.5 mm FERMACELL fibre gypsum board

- 100 / 150 mm Styrofoam

- Adhesive

- Mesh, acrylic plaster

External wall section

Elements

Internal, partition wall

Total wall thickness = 10.5 cm

Timber structure made of KVH wood, 60 x 80, 4-sided planed finish with chamfered edges.

Rockwool mineral wool 50 mm.

Fermacell 12.5 mm board on both sides.

Ceiling

Timber structure made of KVH wood, 60 x 80, 4-sided planed finish with chamfered edges.

Rockwool mineral wool 200 mm.

Fermacell 10 mm.

Roof

Roof slope inclination - 30° / 40°Metal sheet / concrete slate.

Timber battens, impregnated 40/40 mm.

Timber counter-battens, impregnated 60/30 mm.

Roof membrane.

Timber trusses, KVH timber rafters, 60×160.

Wood chamber-dried, four-sided planed

Timber truss trusses supported on exterior wall cap beams. Covering is sheet metal on battens and counter-battens. Fermacell ceiling panels mounted to the bottom chords of the trusses. Moisture and thermal insulation laid at the level of the lower chord.Roof covering - steel sheet tiles on battens and counter-battens.Roof structure - truss, truss spacing - 90cm.Timber - coniferous species, grade C 24, KVH.The roof structure is supported on load-bearing walls by wooden plate girders.

Included in the price of the house.

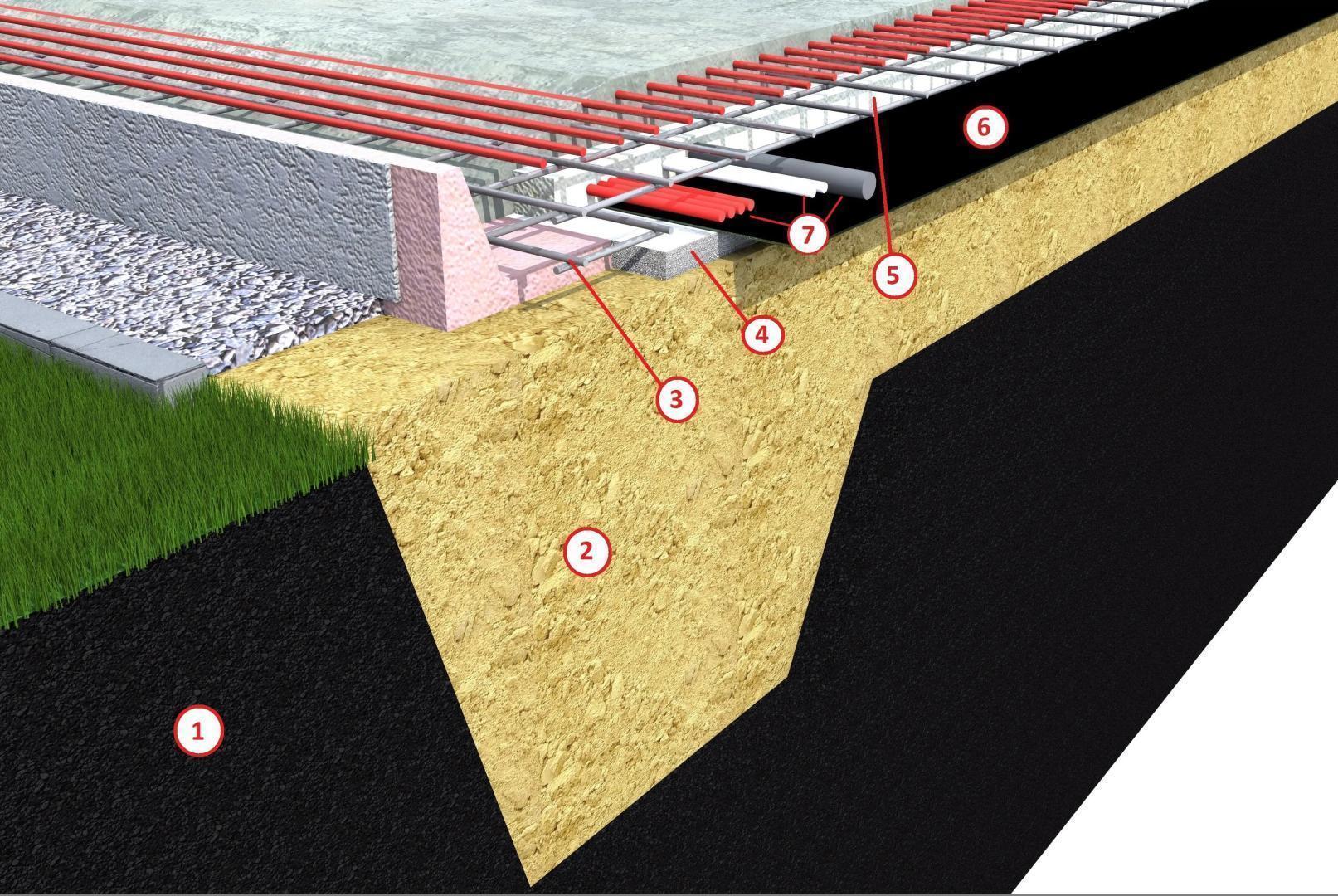

Foundations thermoplate

Unlike the usual foundation slabs, the thermoplate is superior to them in terms of workmanship, thermal performance and accuracy, which results in houses founded on it achieving the highest energy efficiency class.

- thermal insulation

- horizontal insulation

- vertical insulation,

- lateral surfaces prepared for the application of marbled plaster,

- water installation,

- sewage system

- central heating installation

- underfloor heating installation (optional)